- Api Standard 570 Pdf

- Api Standards Free Download Pdf

- Api 570 Study Material Pdf Free Download Filehippo

- Free Api 570 Pdf

- Api Standard 570 Free Download

I4I Academy provides API 570 training course (Online Video Training) - API 570 Piping Inspector - for Exam Preparation and is 48 Hours (6 days) program and available online all over the world. Our Students Pass Rate in the API 570 Exam is 95.23%

Hi, this is Bob Rasooli from I4I Academy. We know most people do not like online courses or do not see as effective as an in-person course; that is why we are using video training to simulate the in-person courses for our students.

CALCULATION SUMMARIES FOR API 570 EXAM Sl # Formula Description Formula Description Para/Ref. No Reference Code 1 Soil Resistivity (ohm-cm) = 191.5 x d x R The number 191.5 is a constant that takes into account the mathematical equation for the mass of the Soil, and a conversion factor to convert feet to centimeters. API 570 - Piping Inspection Code API RP 571 - Damage Mechanisms Affecting Fixed Equipment in the Refinery Industry API RP 574 - Inspection Practices for Piping System Components API RP 577 -Welding Inspection & Metallurgy API RP 578 - Material.

Testimony

Khshayar. Y Cologne - Germany

I took two online video training courses by Inspection 4 Industry LLC; API 570 Training Course and API 510 Training Course.

Bob Rasooli has prepared videos in which he describes all main and essential aspects of related standards and exams in the best possible way. He explains everything in detail and covers all subject of the API 510 and API 570 exams. Undoubtedly Bob Rasooli is one of the best in teaching and preparation training for API exams. In addition to videos, each course consists of numerous questions and examples which helped me a lot to pass both of my exams. I highly recommend these training courses.

James. P Houston - USA

If you want to learn API 570 deeply, take Bob's course. His video lessons are fantastic. His ASME IX, B31.3 and API 570 lessons are awesome. There are almost 1000 practice questions which if you practice enough, you will feel very comfortable in the API exam while you are taking the exam.

Each course comes with a handout which you need to review while/or after watching the videos.

When you completed each video session and reviewed the corresponding handout, then you are connected to the practice question portal. You are going to answer the questions for each code section. The system lets you know if your answer is correct or wrong and provides you with code reference that question being taken.

You are going to take a final exam at the end of the course (50 questions open book and 100 questions close book similar to API 510 exam) and receive a certificate from I4I Academy (if you passed the exam). You can take the exam multiple times until you pass the exam.

This API 570 training course with the video training session and practice exam questions will prepare you to take the API 570 Piping Inspector exam and pass the exam.

Full Package - API 570 Online Video Training Prep Course

- Similar to In-Person Course

- Comprehensive Course Handout

- 1000 Practice Exam Question

- Timed Final Exam (Mock-up Exam)

- 48 Hours PDH (Profesional Development Hour) Toward 9 Year Certificate Renewal for American Welding Society (AWS) Certified Welding Inspectors (If Needed)

- 48 Hours Training credit Toward 6-Year Certificate Renewal for Candian Welding Bureau Certified welding Inspectors (If Needed)

- Technical Support (If help needed during the study)

- 4 Month Access

- I4I Academy Certificate

Question? Contact I4I Academy, or Call 1 (949) 383-0564

10% Off - New Promotion Starts November 10, and Ends December 31, 2020 - You do not want to miss this!

You Pay 494.10 USD With Following Promo Code Now!

Use Promo Code: API-EXAM-NO-CHALLENGE

One-Time Payment 549.00 USD

Risk-Free (Money-back Guarantee): You can return this training course up to 48 hours from the time of payment!

If you had a little time to study and did not pass the API exam, you can have this course for another 4 months without any additional charge!

However, if you think you do not need API 570 training and only need practice exam questions, you may purchase only API 570 Practice Test and Exam Question Package.

Highly recommend getting the full package since you might struggle with ASME B31.3, IX questions and API 570 Problems Solving.

Half Package:

- 1000 Practice Exam Questions

- Timed Final Exam (Mock-up Exam)

- 4 Month Access

10% Off - New Promotion Starts November 20, and Ends December 31, 2020 - You do not want to miss this!

You Pay 350.10 USD With Following Promo Code Now!

Use Promo Code: API-EXAM-NO-CHALLENGE

One-Time Payment 389.00 USD

Risk-Free (Money-back Guarantee): You can return this Practice Test and Exam Questions Package up to 48 hours from the time of payment!

If you had a little time to study and did not pass the API exam, you can have this package for another 4 months without any additional charge!

Sample API 570 Training Videos

I4I Academy Certificate for API 570 Training Prep Course

API 570 Training Course - ASME Related Standard

Following items are covered in ASME B31.3 (Process Piping)

- B31.3 Scope and Exceptions

- Owner Responsibility

- Fluid Category, i.e. Category D, Normal Fluid Service, Category M Fluid Service, High Pressure Fluid Service, Sever Cyclic Service

- ASME B36.10 Dimension of Steel Pipe

- Wall thickness Calculation of Stright Pipe, i.e. pressure design thickness, Min Required Thickness, Determination of Pipe Schedule

- Mill Tolerances Consideration

- Joint Quality Factor

- Blank Wall Thickness Calculation

- Impact Test Requirement( evaluation for exemption and test performance requirements)

- Pre- Heating Requirements

- Post Weld Heat Treatment Requirements

- Inspection, Examination and Testing

- Visual Inspection and Volumetric examination (RT & UT)

- Welding Inspection Acceptance Criteria

- Supplementary Examination

- NDE Personnel Qualification Requirements

- Leak Testing Requirements (Hydrostatic and Pneumatic)

- Closure Weld Requirements

- Thermal Expansion

Following items are covered in ASME Section IX (Welding Qualifications)

- WPS, PQR and WPQ Definition as per Section IX

- Manufacturer Responsibility Regarding Welding

- P, F, A numbers / Group Number

- Essential, non-essential and supplementary essential variables

- SFA Specification and AWS Classification

- Write and Qualify a WPS Without Impact Testing Requirements

- Discuss Welding variable ( Joint Design, Base Material, Wall Thickness Range, Filler Metal, Position, Pre-heat Temp, Interpass Temp, PWHT Temp and Holding Time, Gas or Flux, Electrical Characteristics, Technique, etc.)

- Welder and Welding Operator Performance Qualification

- Qualifying with the Volumetric Method or Mechanical Testing / Requirements

- Qualified Positions, Pipe diameter, Wall Thickness, etc.

- Standard WPS's

- Write and review a WPS with Impact Test Requirements

Following items are covered in ASME Section V (Nondestructive Examination)

Article 1 - General Requirements

- Procedural Requirements

- Personnel Qualification Requirements

Article 2 - Radiography

- Backscatter Requirements

- Density Limitation

- Image Quality Indicator requirements and selection

- Radiography Techniques / Requirements

- Geometric Unsharpness Requirements

- Reporting Requirements

Article 6 - Liquid Penetrant Examination

- Detectable discontinuities

- Surface Cleaning Requirements

- Temp Limitation

- Control of Contaminations

- Penetrant Types (Visible and Fluorescent)

- Type and Categories (Water washable, Post emulsifying, Solvent removable)

- Developer Application Requirements

- Evaluation Requirements

- Black light Requirements

Article 7 - Magnetic Particle Examination

- Detectable discontinuities

- Cleaning Requirement

- Temp Limitation

- Surface Contrast Enhancement Requirements

- Different techniques i.e. Yoke, Prod and corresponding requirements

- Visible and Fluorescent Types

- Calibration requirements

- Lifting of weight requirements

- Method of examination

- Magnetizing Intensity Requirements (Gaussmeters, Pie-Shaped Magnetic Particle Field Indicator, Artificial Flaw Shims )

Article 10 - Leak Testing

- Testing Medium Requirements

- Pressure Gage Requirements

- Temp Limitation

- Leak Testing Techniques

Article 9 - Visual Examination

- Direct Visual Examination Requirements

- Light Intensity

- Annual vision Test Requirements

- Remote Visual Inspection

SE-797 UT Thickness Measurement

Article 4 - Ultrasonic Testing

- Only Definition and understanding of A, B and C Scan

ASME B16.5 Pipe Flanges and Flanged Fittings - Almost Entire Documents

API 570 Training - API Included Standard and Recommended Practices

API STD 570, Piping Inspection Code: Inspection, Repair, Alteration, and Rerating of In-Service Piping Systems - Entire Document

API RP 574, Inspection Practices for Piping System Components - Entire Document

API RP 577, Welding Inspection and Metallurgy - Entire Document

API RP 578, Material Verification Program for New and Existing Alloy Piping Systems - Entire Document

Api Standard 570 Pdf

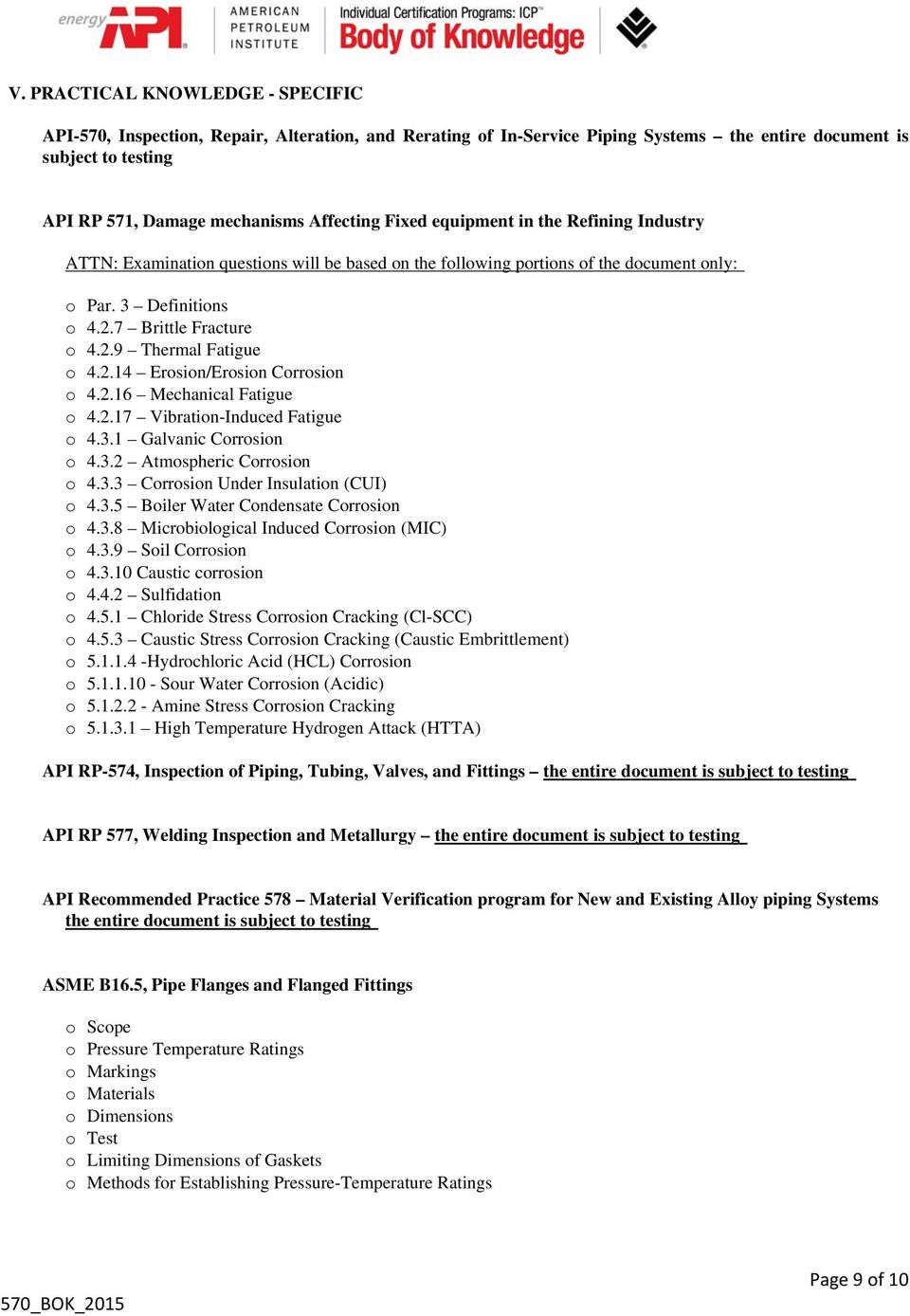

API RP 571, Damage Mechanisms Affecting Fixed Equipment in the Refining Industry

- Section 3 - Definitions

- 4.2.14 – Erosion/Erosion-Corrosion

- 4.2.16 – Mechanical Failure

- 4.3.1 - Galvanic Corrosion

- 4.3.2 – Atmospheric Corrosion

- 4.3.3 – Corrosion Under Insulation (CUI)

- 4.3.5 - Boiler Water Condensate Corrosion

- 4.3.8 - Microbiologically Induced Corrosion (MIC)

- 4.3.9 Soil Corrosion

- 4.3.10 – Caustic Corrosion

- 4.4.2 – Sulfidation

- 4.5.1 – Chloride Stress Corrosion Cracking (Cl - SCC)

- 4.5.3 – Caustic Stress Corrosion Cracking (Caustic Embrittlement)

- 5.1.1.4 – Hydrochloric Acid (HCl) Corrosion

- 5.1.1.10 --Sour Water Corrosion

- 5.1.2.2 – Amine Stress Corrosion Cracking

Return to I4I Academy

Did you find this article useful? Click on below Like and G+1 buttons!

New! Comments

Have your say about what you just read! Leave me a comment in the box below.Hottest and most accurate API API-571 pdf exam study material are written according to the latest API-571 pdf real IT exams. All the API API-571 pdf exam practice questions and answers are revised by the http://www.passitdump.com/API-571.html skillful experts. 100% success and guarantee to pass API-571 exam test quickly and easily at the first attempt.

Question No : 1

_________ is the main concern during start-up, shutdown and/or hydro testing for equipment/piping operating at elevated temperatures. This event can also occur in an auto refrigeration event in units processing light hydrocarbons.

A. Stress fracture

B. Carburization

C. Spheroidization

D. Brittle fracture

Answer: D

Question No : 2

Fatigue will not occur in carbon steel if stresses are below the: Latest API API-571 pdf exam questions and answers

A. Transition limit.

B. Endurance limit.

C. Hardening limit.

D. Speed limit.

Answer: B

Question No : 3

________ has been a major problem on coke drum shells.

A. Thermal fatigue

B. Stress cracking

C. Erosion

D. Temper embrittlement

Answer: A

Api Standards Free Download Pdf

Question No : 4

The “L” grade of stainless steels will sensitize if exposed more than several hours above _______ or long term above _____.

A. 1200º F, 800º F

B. 1000º, 600º F

C. 1000º F, 750º F

D. 1100º F, 800º F

Answer: C

Question No : 5

Once cracking from LME has occurred, grinding out the API-571 vce affected area ______ an acceptable fix.

A. Is

B. Is not

C. Can be

D. Can not be

Answer: B

Api 570 Study Material Pdf Free Download Filehippo

Question No : 6

Ferritic stainless steels are usually not used in __________ applications.

A. Non-pressure boundary

B. Pressure boundary

C. High temperature

D. Low temperature

Answer: B

Question No : 7

In general, the resistance of carbon steel and other alloys to High temperature corrosion is determined by the ________ content of the material.

A. Molybdenum

B. Chromium

C. Carbon

D. All of the above

Answer: B

Free Api 570 Pdf

Question No : 8

Conditions favoring carburization include a high gas phase carbon activity and _______ oxygen potential.

A. Low

B. High

C. Negative

D. Positive

Answer: A

Question No : 9

It is generally accepted that stresses approaching _________ are required for SCC to occur so that API-571 dumps thermal stress relief is effective in preventing caustic SCC.

A. MAWP

B. Yield

C. Creep range

D. Critical

Answer: B

Question No : 10

Low creep ductility is __________ severe in high tensile strength materials and welds.

A. More

B. Less

C. Usually

D. Not

Answer: A

Api Standard 570 Free Download

Question No : 11

Many thermal fatigue cracks are filled with:

A. chlorides.

B. hydroslime.

C. oxides.

D. sulfides.

Answer: C

Question No : 12

Titanium Hydriding damage occurs primarily in sour water strippers and amine units in the overhead condensers, heat exchanger tubes and other titanium equipment operating above _________.

A. 300º F

B. 270º F

C. 210º F

D. 165º F

Answer: D

Question No : 13

Heat treatment can have a significant effect on the toughness and hence fatigue resistance of a metal. In general, ________ grained microstructures tend to perform better than _________ grained.

A. Fine, Course

B. Austenetic, martensitic

C. Course, Fine

D. Martensitic, austenetic

Answer: A

Question No : 14

____________ is a form of environmental cracking that can initiate on the API-571 exam surface of high strength low alloy steels and carbon steels with highly localized zones of high hardness in the weld metal and HAZ as a result of exposure to aqueous HF acid service.

A. Sulfide stress cracking

B. Hydrogen stress cracking

C. Caustic stress cracking

D. Hydrogen induced cracking

Answer: B

Read more: http://www.passitdump.com/API-571.html API API-571 ICP Programs exam training material in PDF format, which is a very common format found in all computers and gadgets. Regardless of whichever computer you have, you just need to download one of the many PDF readers that are available for free. API API-571 pdf exam ICP Programs is the industry leader in information technology, and getting certified by them is a guaranteed way to succeed with IT careers. We help you do exactly that with our high quality API ICP Programs Corrosion and Materials Professional training materials.

Reference: http://www.api.org/products-and-services/individual-certification-programs/certifications/api571