ERW pipe is the fastest and most efficient tube method, but when produced, there are a variety of high frequency tube welding defects. Analysis of the frequency of inclusions in steel production, the pre-arc fusion inadequate inadequate edge fusion, central fusion deficiencies, stick welding, casting welding, porosity, skip welding and other. Section WFP 2-01 – Welding Fabrication Procedure Rev. 1, 10/27/06 Attachment 2, ASME B31.3, “Process Piping” Acceptance Criteria Page 3 of 4 FILLET WELD PROFILES AND SLIP-ON / SOCKET WELDED FLANGES WELD PROFILES Equal Leg Fillet Weld The “size” of an equal leg fillet weld is the length of the largest inscribed right isosceles triangle. Weld metal porosity is a cavity-type of welding defect formed by gas entrapment during solidification as a result of contamination by certain gases, such as hydrogen, oxygen, or nitrogen. Porosity caused by hydrogen pickup can be minimized by keeping the weld joint area and filler metal free of hydrocarbon contaminants and moisture.

Welding disabilities are the deviations in shape and size of the metal structure compared to design standards and technical requirements, which reduces their durability and productivity. Welding defects are formed during welding process

In the common types of weld defects, crack is the most dangerous form and almost all standards do not accept the appearance of crack.

1. Weld crack

It is the most serious defect of the solder joint. Cracks may appear on the surface, inside the weld or heat efected zone

Crack can occur at different temperatures:

+ Hot crack: This appears during the crystallization of weld joints when the temperature is quite high (over 10.000C).

Cold crack: It presents at the end of welding at temperatures below 10,000 ° C, which can appear after several hours, several days after welding.

Weld crack

Causes of crack:

Crack is one of the most dangerous and unacceptable defects because it is highly transmissible. From a small crack, if it does not detected and get rid of in time, the entire part of the involved welds can be cracked for a short time, which leads to all structural damage.

Remedies of crack:

- Use approriate material.

- Release clamping force for welding joints in the welding process. Increase fill to capacity of welding material.

- Preheating for weld, keeping heat for weld joint to reduce the cooling speed.

- Use reasonable weld joints, beveled edges reduce the gap between welding objects ...

- layout spacing welds.

2. Blow hole

It is formed due to the gas phenomenon in liquid metal. The weld can not escape when metal puddles solidified

Blow hole can be appeared:

+ Inside (1) or weld surface (2)

+ Located at the boundary between base metal and fill metal

+ Can be distributed, concentrated (4) or discrete in the weld

Blow hole

Causes of blow hole

Welds existing porosities will reduce their effectiveness and tightness

+ C content in basic metals and in weld materials is too high

+ Welding material is damp, the surface of the welding is dirty

+ The arc length is large, the welding velocity is too high

Remedies of blow hole:

+ Adjust the short arc length, reduce the welding speed of the MIG welding machine

+ After welding, do not knock the slag immediately to prolong the heat retaining time for the weld

+ provide enough MAG welding / MIG gas, gas shooting distance

+ Automatic welding flux is not moist, providing enough flux in the welding process

3. Slag inclusion

This defect is easily presented in the weld, the slag may exist:

+ In welding

+ On the surface of the weld

+ The boundary between basic metal and metal welds, between welding turns

Slags affect the impact toughness and metal weldability of the weld, which reduces the structural performance of the weld.

Causes of slag inclusion:

Welding current density is too small ,which is difficult to provide enough heat for molten metal and it leads to the fact that slag might be impossible to float on the weld surface

+The welding speed is too fast.

+The weld edge is not completely cleaned or workers do not remove layers of slag before welding.

+Welding angle and travel rate of welding rod are not suitable.

+Welding pool is cooled down too fast to float slags

Remedies of slag inclusion:

Increase current density and increase the arc stop period.

- Adjust the welding speed, don't let occur the situation of mixture between slag and the weld pool or slag flows forward in the melting zone

- Clean up the edge and get rid of all slags of the previous welding layers before welding

- Make an approriate adjustment for the electrode angle and electrode travel rate

- Reducing rapid cooling of the weld pool

4. Incomplete fusion

A serious defect in the solder joint leads to the crack that damages the bond

Causes of incomplete fusion:

+ Prepared welds are not right

+ Welding current is too small or too fast

+Electrode angle (electrodes) and the way to put the electrode is not suitable

+ Arc length is too large

+ The welding electrodes are not exact travel rate according to the welding shaft

Remedies of incomplete fusion:

+ Clean the joint before welding, increase beveled corner and weld gap.

+ Increase welding current and reduce welding speed, etc.

5. Undercut

Reduces the working effect of the link. Creating high stress can lead to structural damage

Squeeze your legs, flow

Causes of undercut:

+ Welding current is too large

+Large arc length

+ Angle and placement of welding rod is not reasonable

+ Incorrect use of welding electrode size (too large)

6. Overlap

The phenomenon of liquid metal spills on the surface of the welding bond (basic metal surface is not melting)

Causes of overlap:

Incorrect angle of welding rod

+ Welding current is too high

+ Weld placement and placement of unsuitable materials

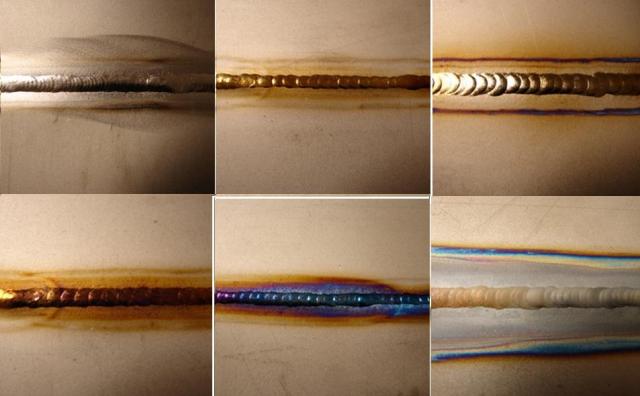

7. Defect of joint shape

- Include deviations in appearance of the weld joint:

+ Height of the protruding, uneven weld width

+ Welded lines

+ Weld unevenly

Causes of defect of joint shape

+ Fixing, preparation of welds are unreasonable

+ Unstable welding mode

+ Non-qualified welding materials

+ Technology level is too low

- Over temperature: Because welding mode selection is wrong ( thermal energy is large, Vh is small )

Solution:

If the types of welding defects are discovered, the process requires:

- Remove metal parts with defects.

- Repair and recheck.

- Particularly for cracks, it is necessary to block the two ends of the crack to limit the development of cracks, eliminate thoroughly and repair again

- Overheat defects should be prevented to restore size of the weld metal and heat-sensitive area.

- » Plasma arc welding (06/05)

- » Basic arc welding technique (06/05)

- » Currently there are many types of welding machines come from the brands with the cost and quality (06/05)

- » How to choose a good stick welding machine? (06/05)

- » Difference between MIG welding and MAG welding (06/05)

- » Advantages and disadvantages of MIG welding machine vs TIG welding machine (06/05)

- » Welding technique of aluminum and aluminum alloy (06/05)

7 Most Common Defects In Welding and its causes

Welding Defects

Different Types of Welding Defects

- poor ductility of base metal,

- high sulpher and carbon contents,

- high arc travel speeds i.e. fast cooling rates,

- too concave or convex weld bead

- high hydrogen contents in the weld metal.

2. Distortion/ Imperfect Shape

Pipe Welding Defects Chart

- Lamellar tearing is a type of welding defect that occurs in rolled steel plates that have been welded together due to shrinkage forces perpendicular to the faces of the plates.

- Lamellar tearing is caused mainly by sulfurous inclusions in the material. Other causes include an excess of hydrogen in the alloy. This defect can be mitigated by keeping the amount of sulfur in the steel alloy below 0.005%

- Modifying the construction process to use casted or forged parts in place of welded parts can eliminate this problem, as Lamellar tearing only occurs in welded parts.

Pipe Welding Defects Welding

7.UnderCutting :

Undercutting is when the weld reduces the cross-sectional thickness of the base metal and which reduces the strength of the weld and workpieces. One reason for this type of defect is excessive current, causing the edges of the joint to melt and drain into the weld; this leaves a drain-like impression along the length of the weld. Another reason is if a poor technique is used that does not deposit enough filler metal along the edges of the weld. A third reason is using an incorrect filler metal, because it will create greater temperature gradients between the center of the weld and the edges

Read More Related to welding :

Related posts: